Roger

Fuller now has a new website at www.canalnarrowboats.com

this page is an archive only. |

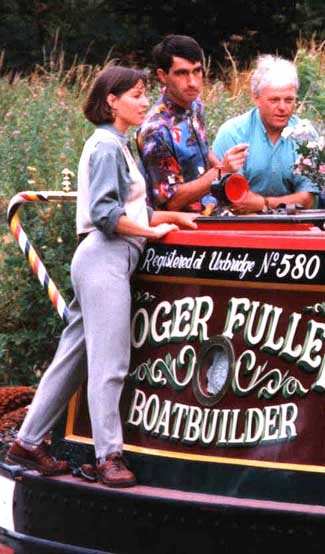

New Boats, From Roger Fuller.

Roger Fuller has been boatbuilding full time since 1985, and constructed from scratch over 35 craft to all stages of completion. He is a member of the Canal Boatbuilder's Association; the British Marine Federation, and is accredited as MASTER BOATBUILDER with the Waterways Craft Guild. Having a good grounding in traditional narrow-boats, spanning 25 years, he has built a company based on boating experience. He is able to design hulls and interiors from scratch, and can advise on the practicalities of designs presented. The company has a canalside industrial unit capable of holding 2 x 70ft narrowboats, with engineering facilities for installing engines, shot blasting hulls, building, and repairing narrowboats. Our dedicated woodworking area allows us to machine English and foreign hardwoods and softwoods, and offer a full fitting out service.

The company is based at Stone, on the Trent and Mersey canal in North Staffordshire. Our boatyard is canalside to the North of the town, and has moorings available. We can also offer boat blacking; stern gear inspection, and full repaints, to keep you afloat; going forwards, and looking good..

|

|

Under construction.......................................................................the finished fore-end.

All our boats are ''one off'', and as such we cannot give a price without a specification. Have a look at the photo gallery, and see the variety of craft designs that FTB has built.

If you are thinking of placing an order, you need to think ahead. We currently have 24 months work, and the list grows by the week. You will need to know what you want, and if you don't; well, no problem; just tell us, and we can design a boat by discussing all the options with you, so that you can make the right decisions. Quality costs money, so don't be surprised when we give you finished prices in the range of £1,200 to £1,500 per ft length of boat.

Your early decisions will include your engine choice; old or new; 2,3, or 4 cylinder, (or more!). We favour Gardner Diesels, either new or professionally rebuilt; try Tony and Paul Redshaw, (01788 553417). You will not come across a finer engine for a narrowboat. To get a quality engine of this type, you will need to think ahead, and get your name on the list.

|

Gardner Diesels were made in multiples of 1 to 8 cylinders, the most popular for narrowboats being 2 and 3 cylinder versions. The LW range is the most prolific, followed by the earlier L2 engines, and lastly the most recent production model, the LK. Many of these engines have been marinised, and come from varied backgrounds; generators, railway locomotives etc. |

..Gardner 4LW; rebuilt by Paul Redshaw ready for installation.

Design. Potential boat owners come from many varied backgrounds, and experience. You may be completely new to boating, or have been at it for years. Buying a new boat involves making many decisions; we're here to help, to study your designs; offer suggestions, and make sure the correct decisions are taken in the design stage. Typical boat designs include tugs, narrowboat cruisers, working boats, Dutch barge style boats, and individual designs from you, the customer.

|

|

...............Newly completed narrow beam Dutch barge.................................................Welding in progress!